Choosing wooden panels for outdoor use is crucial to ensure a perfect balance between strength,

lightness and durability. Used especially in the mobile home sector, every kilogram saved in these

panels helps improve efficiency, manoeuvrability and comfort, making high-quality materials a

strategic investment.

Our panels are the result of decades of research and innovation: they combine high mechanical

performance with selected materials. The result is a lightweight but solid, stable and reliable

product over time, even under intensive use.

Thanks to full customization, we manufacture tailor-made panels for walls, floors, roofs and interior

cladding, even for areas exposed to humidity. This flexibility allows manufacturers to develop

bespoke solutions that combine aesthetics, functionality and durability.

From lightness to strength: how panel design evolves

The main challenge in designing outdoor panels is to balance lightness, stability and resistance to

atmospheric agents.

Continuous investment in research and development has enabled us to introduce innovative

technical solutions capable of ensuring excellent performance even in humid or exposed

environments. The use of Italian poplar from short supply chains, precise gluing processes and the

possibility of melamine or HPL laminate finishes offer versatility, ease of processing and good

insulating properties.

Each Filippi 1971 panel is the result of a production process controlled at every stage: certified

quality, material traceability and maximum safety in production cycles. More than simple

construction elements, our panels represent a long-term investment, synonymous with reliability

and performance.

Our panels for outdoor applications

Our expertise allows us to offer panels with fully customizable features: calibrated thicknesses,

specific finishes and treatments that extend their durability. All panels are made with selected

woods for stability and resistance, ensuring consistent performance even in humid conditions or

temperature fluctuations.

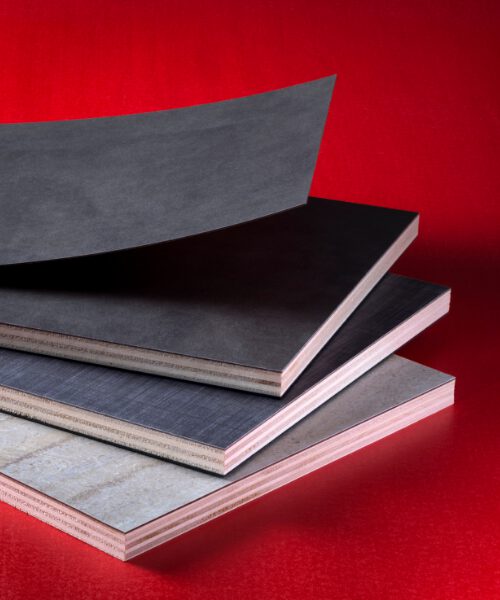

HPL Laminates

HPL (High Pressure Laminate) panels are made from multiple layers of kraft paper impregnated

with thermosetting resins, pressed at high temperature and pressure. The result is a material that

combines high resistance to wear, heat and humidity, making it ideal for applications requiring

durable surfaces that withstand frequent stress, such as floors and walls.

Technical specifications:

- Thickness: 0.9 mm to 12 mm

- Dimensions: up to 3050 × 1300 mm

- Additional features: aesthetic customization (digital printing), glossy, matt or wood-effect finishes

- Applications: flooring, recreational vehicles, nautical sector

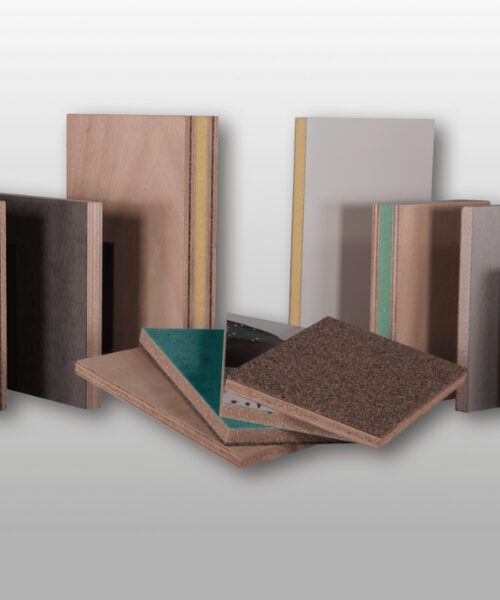

Sandwich panels

Sandwich panels combine lightness, rigidity and excellent thermal and acoustic insulation. They

are composed of two rigid surfaces (e.g., poplar) and a lightweight polystyrene core. They are

perfect for applications requiring high mechanical performance and good insulation, such as walls

and roofs of recreational vehicles (motorhomes, caravans) or industrial structures.

Technical specifications:

- Thickness: from 14 mm to 120 mm

- Dimensions: up to 4000 × 1500 mm

- Thermal insulation: excellent thanks to the internal structure

- Application sectors: automotive, nautical, construction, prefabrication

- Materials used: Poplar plywood, EPS, XPS, PET, high-density rubber, calcium silicate, aluminium,

okoumé. Panels are ennobled with finishes designed for outdoor use.

Poplar plywood panels

Poplar plywood panels are made of cross-laid selected veneers, offering good stability, lightness

and excellent workability. These panels are ideal where a good balance between weight and

strength is needed, such as in furniture or lightweight structures.

Technical specifications:

- Thickness: 6 mm to 40 mm

- Dimensions: up to 2500 × 1250 mm

- Features: good resistance to impacts and deformation

- Applications: furniture, lightweight constructions, packaging, recreational vehicles

How to choose wooden panels for outdoor use: the ideal guide

When evaluating wooden panels for outdoor use, consider the following criteria:

- Intended use: vertical wall, outdoor flooring, ceiling, screening—each requires specific technical

features. - Wood or composite type: natural wood (fir, larch, teak etc.) vs composite/WPC. Composites

offer greater stability and lower maintenance. - Durability class and treatment: ensure the panel is certified for outdoor use (UV, humidity,

pests). - Installation system: consider substructure, ventilation (in ventilated façades), mechanical fixing,

interlocks and joints. - Maintenance: consider protective treatments and ease of repair/replacement.

- Aesthetic compatibility: ensure the chosen wood matches the architecture; orientation

(horizontal/vertical) affects the final appearance.

Main applications

Wall cladding / façades

One of the most common applications is vertical wall cladding. Wood helps:

- create a natural and warm look, blending with the surroundings

- provide good thermal and acoustic insulation

- simplify installation through modularity

Examples: natural wood for ventilated façades, horizontal/vertical slats, technical wood or WPC

panels installed on substructures.

Outdoor flooring and decking

Wooden (or composite) panels are used for terraces, pool areas, porches and outdoor spaces.

Outdoor wood must be treated or certified for resistance to weathering. This creates continuity

between indoors and outdoors, with natural aesthetics and often anti-slip properties.

Outdoor ceilings and partial coverings

Used in verandas, porches and shelters as ventilated ceilings or horizontal finishes. Some natural

wood panels are designed specifically for external horizontal use requiring UV and water

protection.

Screens, brise-soleil and outdoor partitions

Wood or composite panels can be used as sun-shades, privacy screens, partitions, grilles or

decorative panels.

Outdoor panels for the Mobile Home sector

Alongside the classic plywood range, Filippi 1971 offers lightweight, technical melamine-faced

panels developed specifically for mobile homes:

- Melamine-faced panel with poplar OSB core: excellent weight-to-performance ratio, moisture-

resistant, formaldehyde-free (CL2, EN 335). - Melamine-faced panel with poplar LSB core: smooth, uniform, lightweight surfaces. MDI glue

ensures moisture resistance (CL2, EN 335). - Melamine-faced panel with poplar chipboard core: 100% virgin poplar chips, lightweight, easy

to machine, good mechanical strength.

Custom quotes and technical consulting

Our strength lies in the combination of experience, material quality and continuous innovation. We

merge craftsmanship with modern technologies to deliver uniform, precise and highly resistant

panels. Each material is carefully selected to minimize deformation and wear.

We offer customized solutions for recreational vehicles, marine furnishings and residential or

contract environments.

Sustainability is central: we use Italian poplar from controlled plantations and local suppliers, and

recyclable, low-formaldehyde materials with MDI bonding.

Our technical support is available at every stage

Choosing Filippi 1971 means relying on a competent partner offering personalized consulting, fast

responses and continuous assistance.

FAQ about wooden outdoor panels

1. What are the best wooden panels for outdoor use?

HPL, sandwich and plywood panels depending on application and climate.

2. Why choose wooden outdoor panels?

They combine natural aesthetics with resistance to atmospheric agents and offer high

customization.

3. How should outdoor wooden panels be maintained?

Regular protective treatments (painting/oiling). Composite and HPL require less maintenance.

4. Can wooden panels be used in humid environments?

Yes, if they are treated or designed for humidity, such as HPL or sandwich panels.

5. How do I choose the right panel for my project?

Assess the application, required dimensions, climate and resistance to thermal/humidity variations.