The term coated panels is widely used in the market, but it is often associated with standard products, cut-to-size solutions and price-driven purchasing logic.

In the industrial and B2B context, however, its meaning changes significantly.

For companies operating in the furniture, marine and recreational vehicle sectors, coated panels represent a technical solution designed to ensure stability, surface resistance, consistent quality and seamless integration into production processes.

With this article, we clarify what is meant by coated panels in a professional context and which technical aspects should be considered when selecting the most suitable solution for specific industrial requirements.

What are coated panels

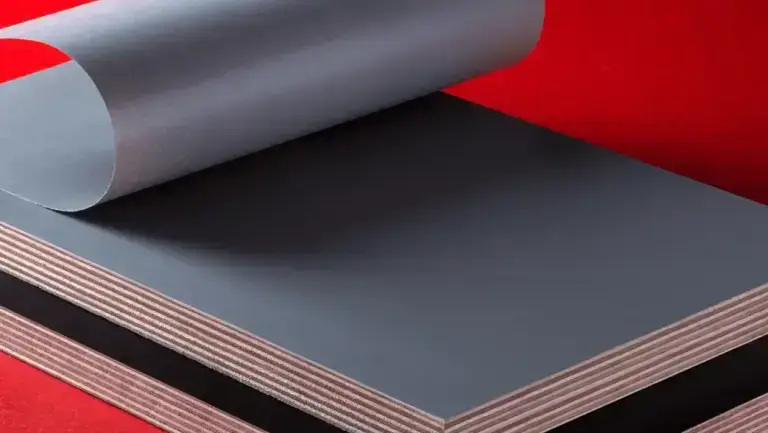

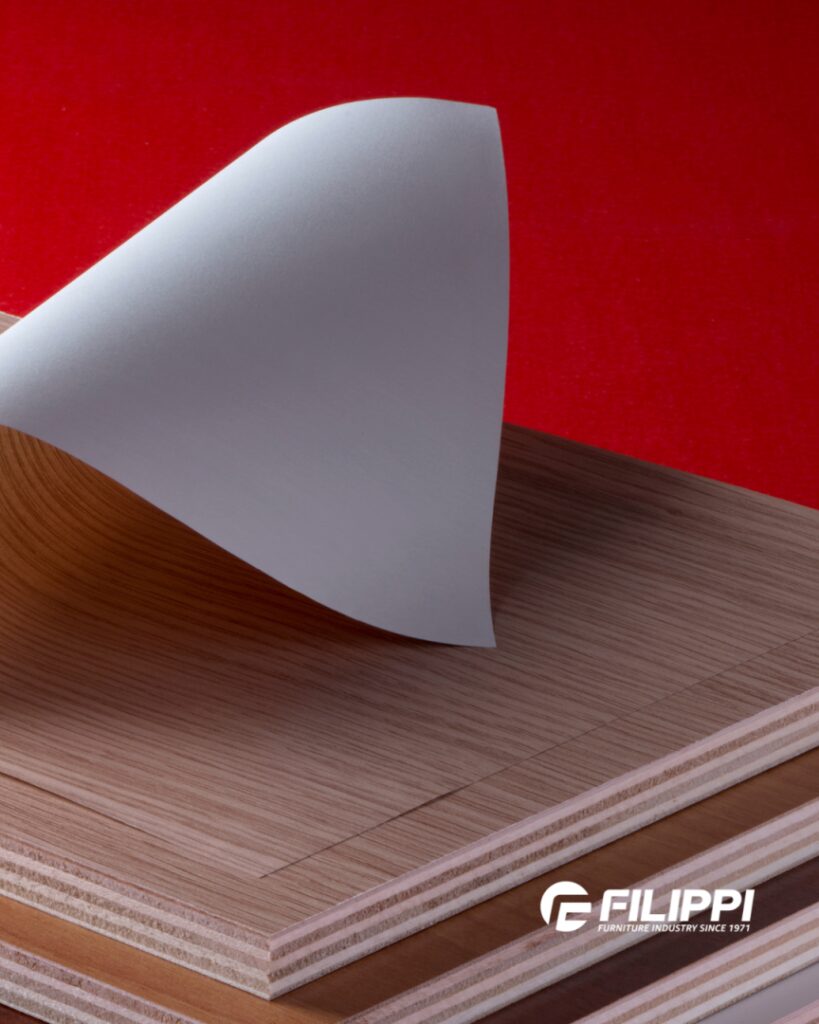

Coated panels are products based on chipboard (or other wood-based and non-wood materials) that are covered with technical or decorative materials to improve their functional and aesthetic performance. The value of the panel lies primarily in the panel + coating system.

At Filippi 1971, coated panels combine carefully selected substrates with technological films and high-quality surface materials, including HPL/CPL laminates, real wood veneers, melamine papers, Alkorcell, PET and PVC, ensuring high performance, customization and durability even in demanding applications.

The role of the chipboard substrate

Chipboard provides a stable, flat and homogeneous base suitable for industrial processing. It is a widely used substrate when regular surfaces and production repeatability are required.

Depending on the final application, the substrate is selected carefully: in addition to chipboard, Filippi 1971 also works with other technical substrates when the project requires specific characteristics in terms of weight, strength or moisture behavior, while always keeping the coating as the key element of the panel’s final performance.

The coating as a functional element

Beyond its aesthetic function, the coating protects the panel, improves its wear resistance, facilitates cleaning and contributes to the product’s long-term durability, especially in high-use environments.

From raw material to ready-to-use panel

Coated panels for B2B are finished products designed to be directly integrated into furniture, walls, technical components or complex furnishing systems, without the need for further treatments.

Thanks to our integrated digital printing systems, it is possible to obtain unique decors, reproductions of natural surfaces (such as marble or rare wood grains) and customized finishes without minimum quantities, offering solutions perfectly integrated into production cycles.

Why the coating is a key element

In the industrial context, the coating determines a large part of the panel’s performance. Below are three examples.

1. Wear and abrasion resistance

Coated surfaces are designed to withstand intensive use cycles, frequent contact and mechanical stresses typical of professional environments.

2. Surface stability and ease of maintenance

A suitable coating ensures that the surface remains stable over time. This reduces dirt absorption and simplifies cleaning operations.

3. Aesthetic uniformity in mass production

In industrial processes, it is essential to guarantee color and texture continuity across different batches. The coating makes it possible to achieve consistent and controlled results.

Types of coatings applicable to panels

Within the panorama of coated panels, several coating types are used in professional contexts. In particular:

Decorative and technical coatings

These coatings protect the substrate and provide uniform surfaces suitable for contexts where aesthetics and functionality must coexist. Among the most common coatings are melamine-based decorative surfaces, used when aesthetic uniformity, ease of cleaning and good wear resistance are required in industrial applications.

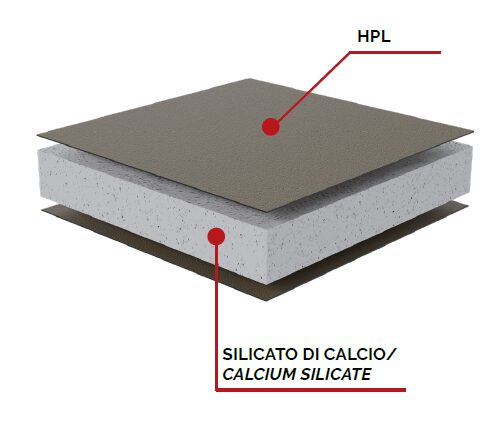

HPL stratified laminates

HPL (High Pressure Laminate) is used when high surface performance is required. It offers resistance to scratches, impacts, detergents and moisture, making the panel suitable for more demanding applications.

Other coating materials

Other coating materials include plastic films such as PET or PVC, high-performance decorative papers, real wood veneers and CPL laminates, which allow surfaces with specific textures, finishes and aesthetics while maintaining resistance and mechanical stability.

In which sectors are coated panels used

Thanks to their versatility, coated panels are used in various industrial sectors:

Furniture and interior design. Used for furniture, wall systems and interior surfaces, where aesthetic quality, stability and ease of maintenance are required.

Campers, caravans and recreational vehicles. In the RV sector, they are used for interior components that must maintain consistent performance over time and integrate with serial production cycles.

Marine. In the marine sector, coated surfaces help protect the substrate from moisture and ensure durability and safety in interior environments. Moisture resistance does not depend solely on the substrate itself, but on the type of coating applied and the overall panel protection system.

Technical aspects to evaluate when choosing

Selecting the most suitable coated panels for industrial use requires careful technical analysis. Below are three key aspects to consider:

1. Emissions and regulatory compliance

It is essential to verify compliance with European emission standards, such as E1 class and REACH requirements, especially for indoor applications. The panel’s technical data sheet provides essential information on emissions, coatings and intended use, and is the primary tool for objectively comparing industrial solutions.

2. Long-term stability

The panel’s behavior must remain predictable even in the presence of temperature or humidity variations. The coating plays a decisive role in this aspect.

3. Compatibility with industrial processing

The choice of adhesive type (for example vinyl D3/D4, melamine or polyurethane) affects the durability of the coating itself, its stability under varying environmental conditions and the final resistance of the panel to mechanical stress.

Cutting, edging, bonding and assembly must take place without compromising the integrity of the coating and the final product quality. This also includes edging and edge protection, which are essential elements to preserve the panel over time and reduce substrate exposure in environments subject to moisture or wear.

The value of an industrial solution compared to a standard product

In B2B, coated panels are selected based on measurable performance, production consistency and integration into the industrial process.

Unlike standard products intended for the retail market, coated panels for professional applications must guarantee predictable long-term results, compatibility with industrial processing and continuity between production batches.

For this reason, evaluation involves the entire system: material, coating, finish and process.

Three key elements distinguish an industrial solution from a standard product:

Quality continuity

In serial production, even small variations in surface, color or mechanical behavior can compromise the final result.

Quality continuity ensures that each panel maintains the same performance and appearance over time, allowing project and production standards to be met without continuous adjustments.

Process control

The quality of coated panels depends not only on the substrate, but also on control over the entire production process: raw material selection, coating application, surface finishing and intermediate checks.

This approach makes it possible to obtain panels with consistent performance and to reduce variables affecting workability and durability.

Supplier reliability

In B2B, the supplier is an industrial partner, called to support the project throughout its entire lifecycle. Filippi 1971 supports its customers by guaranteeing supply continuity, technical assistance already at the design stage and the possibility of adapting panels and coatings to specific application requirements.

An approach that ensures high quality standards and full regulatory compliance, even in serial production and in the most demanding sectors.

FAQ – Coated panels

What is meant by coated panels in an industrial context?

They are chipboard panels (or other materials) coated with technical or decorative materials, designed for professional applications.

Is the coating only for aesthetics?

No. The coating has a technical function: it protects the panel, improves wear resistance and contributes to long-term stability.

Are coated panels suitable for humid environments?

It depends on the type of coating and the application. In the marine sector and in humid indoor environments, the coating is essential to protect the substrate.

What is the difference between standard panels and industrial solutions?

Industrial solutions guarantee consistent quality, regulatory compliance and integration into production processes, aspects that standard products do not always ensure.

How can the quality of coated panels be verified?

Through the technical data sheet, emission certifications, coating information and production process traceability.