Research and Development

Innovating every day to create the materials of the future

The heart of innovation at Filippi 1971 lies in the Research and Development department, established in 2016 with the aim of supporting designers and customers in the creation of custom technical solutions and the development of high-performance, sustainable, lightweight and increasingly versatile materials.

This is where ideas, products and proprietary technologies take shape, tackling the challenges of the present and anticipating the needs of the future. This vision has led to the creation of exclusive brands such as VittEr® and Moitech®, the result of continuous experimentation and listening to the market.

INNOVATIVE MATERIALS AND SOLUTIONS FROM FILIPPI 1971

VittEr®: the laminate that changes the rules

VittEr® is a new generation of technical laminate, conceived and developed by Filippi 1971 to offer a concrete response to modern requirements of safety, sustainability and design.

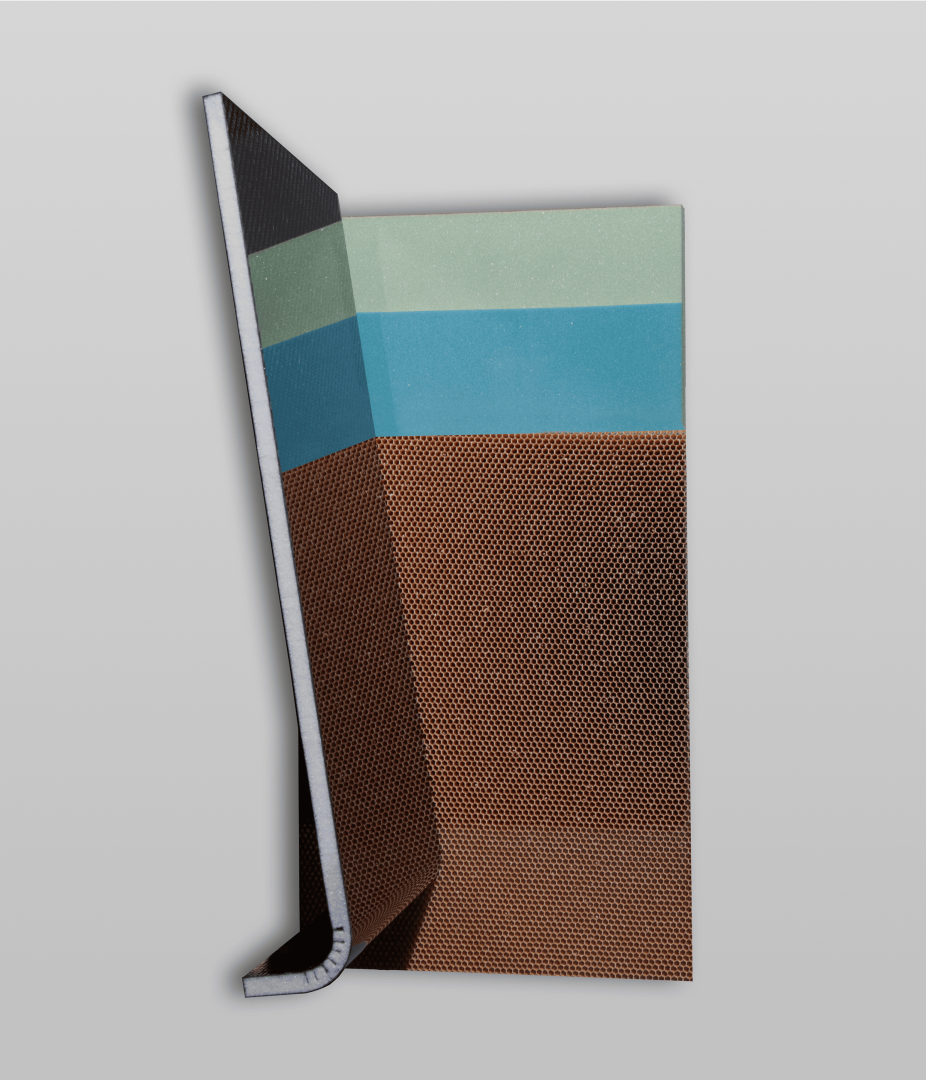

Moitech®

Moitech® is the innovative brand founded in 2017 in the R&D department. Its area of expertise is the world of advanced composite materials, where beauty and technology meet to create enhanced, lightweight, high-performance solutions.

Composite fibre panels

In the Filippi 1971 R&D department we also design custom technical panels based on glass, carbon or linen fibres, depending on specific customer requirements.

Technology serving innovation

Our R&D department boasts cutting-edge tools for the entire development cycle, from design to functional prototyping and industrial pre-production.

Featuring:

- 3D CAD software for modelling and technical design

- 3D printers for prototypes with technical materials (CA-PET Carbon Fibre, ABS)

- Autoclave (4000 x 1280 mm) for advanced lamination up to 120°C and 8 bar

CNC units for moulds and custom components