Lightweight, durable, and precisely crafted: boat and ship bulkheads are at the heart of modern interiors in yachts and nautical construction. For over fifty years, Filippi 1971 has been developing innovative materials that combine design, functionality, and longevity. The company offers custom-made sandwich bulkheads, ideal for walls, ceilings, and floors in various areas of vessels, meeting the highest technical standards.

Why Bulkheads Are Essential

Bulkheads are not mere interior dividers—they play a crucial role in ensuring stability, comfort, and safety on board. In the nautical world, weight and strength are critical. Bulkheads must be lightweight while also withstanding humidity, temperature fluctuations, and mechanical stress.

Filippi 1971 combines advanced materials and production technologies to provide durable, dimensionally stable, and aesthetically pleasing solutions, even for the most demanding applications. Bulkheads separate cabins, common areas, and technical spaces, providing privacy, security, and acoustic insulation. Despite an average thickness of just 20 mm, the technical materials create a comfortable internal environment in terms of both noise and privacy.

In addition to providing thermal comfort and sound insulation, bulkheads must also support shelves, cabinets, mirrors, and other interior accessories in a functional and stable way.

Materials and Innovative Solutions by Filippi 1971

Filippi 1971 offers a complete range of materials designed specifically for yachts and boats, meeting high standards of aesthetics, functionality, and durability.

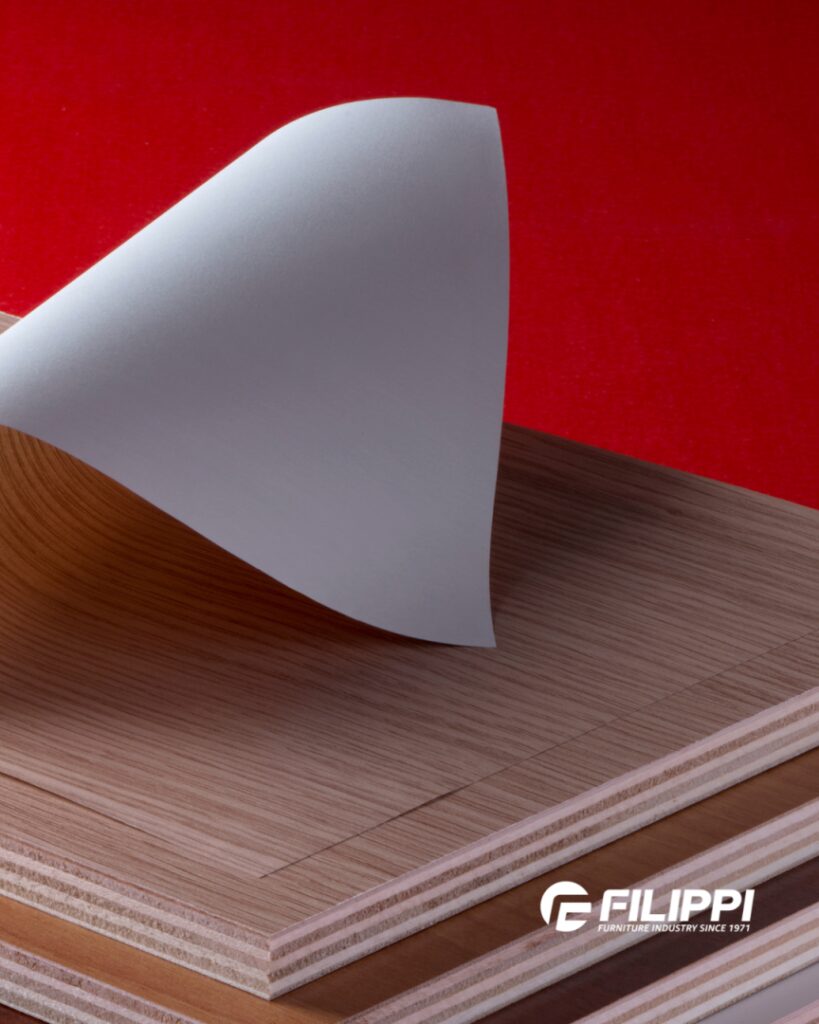

- Decorative Panels

We produce robust and durable decorative panels, made of Okumé marine plywood or mineral-based panels. These materials are ideal for challenging marine environments, perfect for interiors, furniture, and decorative elements on board, thanks to their strength and dimensional stability.

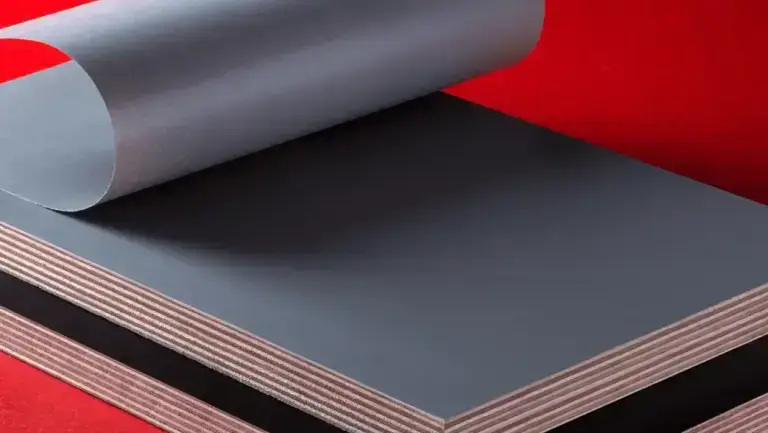

- Sandwich Bulkheads

Sandwich bulkheads combine lightness, stability, and excellent soundproofing properties. Their layered structure makes them ideal for load-bearing structures and internal walls where low weight and high mechanical strength are required, enabling the construction of efficient, durable, and comfortable interiors.

- HPL and compact laminates

For yacht interiors, Filippi 1971 also offers HPL laminates and layered materials, which are durable, versatile, and aesthetically elegant. Ideal for furniture, coverings, and functional surfaces, they can be customized with digital printing to create decorations and designs tailored to the client’s specifications.

By combining natural materials with advanced technologies, Filippi 1971 provides solutions that are visually appealing, functional, long-lasting, and sustainable—perfectly adapted to the needs of modern naval construction.

Design and Customization

Design and Customization

Every vessel is unique. Filippi 1971 bulkheads are designed according to client specifications, assembled with technical and innovative components, CNC-processed, and delivered as complete kits. This approach allows the creation of high-performance, state-of-the-art compartment solutions, ready for installation on board.

Sustainability and Maritime Certifications

Sustainability is a core part of Filippi 1971’s philosophy. The company ensures responsible sourcing of materials, using wood exclusively from FSC® and PEFC-certified sources.

The quality and safety of Filippi 1971 products are supported by international certifications, including ISO 9001 for quality management. Additionally, Filippi 1971 conducts regular tests in collaboration with the CATAS certification laboratory to verify the chemical, physical, and mechanical properties of materials intended for marine use.

Applications in Yacht and Ship Construction

In addition to bulkheads, Filippi 1971 products are used for:

- High-strength floors and structures

- Furniture components and interior coverings

Each element is designed and manufactured according to client specifications, ensuring perfect integration into the overall design of the vessel.

Quality, Innovation, and Sustainability Onboard

Filippi 1971 bulkheads combine technical expertise, Italian design, and artisanal precision, offering lightweight, durable, and visually elegant solutions for the entire interior of yachts and boats. Thanks to continuous research, sustainable material sourcing, international certifications, and custom development, Filippi 1971 remains a reliable partner for shipyards, designers, and architects worldwide.

FAQ

- Which materials are used for boat bulkheads?

Lightweight sandwich or composite panels are commonly used, resistant to humidity and temperature changes.

- Which wood is used for boat bulkheads?

The most common woods are teak, mahogany, or Okumé, valued for their stability, durability, and natural water resistance.

- How thick should wood be for bulkheads?

For interior bulkheads, 10–20 mm is generally sufficient. Custom thicknesses, sizes, and compositions are also available upon request. Available bonding types: vinyl, melamine, and polyurethane.

- Which wood lasts longest in water?

Teak is considered the most durable wood in the maritime environment, thanks to its natural oils and high resistance to moisture.