Fire-resistant sandwich panels are now a fundamental component in marine design, where fire safety represents an essential requirement.

However, it is important to clarify a key point: not all sandwich panels are fire-resistant in the same way.

In this article, we explain how fire resistance works in sandwich panels and which solutions are truly suitable for marine applications.

What is meant by fire-resistant sandwich panels

The term fire-resistant sandwich panels are refers to construction systems designed to offer controlled performance in the event of fire, thanks to the combination of a central core and specifically selected external facings.

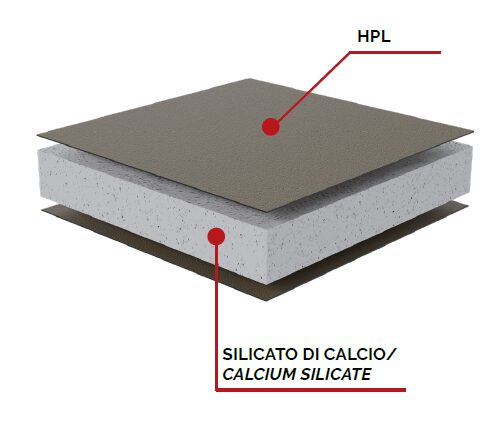

Structure of a sandwich panel

A sandwich panel consists of a core and outer facing surfaces. This configuration makes it possible to obtain lightweight yet rigid panels, suitable for integration into complex structures.

In fire-resistant panels, the core is the element that most affects fire behavior: it determines stability, reaction to high temperatures, and the ability not to fuel combustion. The facings, on the other hand, help protect the panel, ensuring functional and aesthetic continuity.

When a panel can truly be considered fire-resistant

Not all materials described as “fire-resistant” offer the same level of performance. It is essential to distinguish between flame-retardant materials and non-combustible materials.

The former slow down flame spread but may still contribute to combustion; the latter do not fuel the fire and maintain more stable behavior at high temperatures.

In the marine sector, this distinction is crucial: a panel can only be considered truly fire-resistant if its performance is certified through laboratory testing and compliant with relevant marine standards.

What is the fire resistance of a sandwich panel

Fire resistance is a set of measurable performances that describe how a panel behaves under fire conditions.

What fire resistance means

Fire resistance indicates the ability of the panel to maintain specific performances for a defined period when exposed to flames. In particular, it concerns three aspects:

- load-bearing time, meaning how long the panel maintains its function;

- structural integrity, preventing cracks and flame passage;

- thermal insulation, limiting heat transfer to adjacent areas.

Fire resistance classes in the marine sector

In the marine sector, fire resistance is classified according to stricter standards than those used in construction. Classes such as B-15 and B-30 indicate the time, expressed in minutes, during which the panel must maintain the required performance in the event of fire.

Onboard operating conditions – confined spaces, complex systems, presence of people – require a higher level of safety. For this reason, panels must be specifically designed and certified for marine use.

Calcium silicate-based panels: a non-combustible solution

Among the most effective solutions for fire resistance in the marine sector are calcium silicate-based panels, designed to offer stability and safety even in complex environments.

What calcium silicate is

Calcium silicate is a mineral material obtained through controlled industrial processes. In the event of fire, it does not contribute to combustion and retains its shape even at high temperatures, limiting deformation and structural failure.

Advantages in fire-resistant sandwich panels

Using calcium silicate as the core makes it possible to obtain non-combustible, stable, and reliable panels. This is combined with good moisture resistance, making the material suitable for galleys, bathrooms, and technical areas, where other substrates tend to degrade over time.

The role of HPL facing in fire-resistant panels

In fire-resistant sandwich panels, the facing plays a direct role in overall performance. It acts as a protective barrier for the core, reducing exposure to impacts, abrasion, and aggressive agents.

A continuous, well-applied surface limits discontinuities and contributes to panel stability even under critical conditions.

In the marine sector, ease of cleaning and hygiene is an additional key factor, especially in shared and high-traffic areas.

HPL facing: performance and design

HPL high-pressure laminates offer resistance to impacts, scratches, and chemical agents, maintaining consistent performance even under intensive use. At the same time, they provide high aesthetic quality, making the panel suitable for both technical environments and high-end spaces.

SEAWHITE HP: fire-resistant sandwich panel for marine applications

SEAWHITE HP is a fire-resistant sandwich panels specifically designed for the marine sector. It combines a non-combustible calcium silicate core with an HPL facing, offering a complete fire-safe system.

A fire-safe panel designed for marine use

The design of SEAWHITE HP is focused on the needs of shipyards, where safety, precision, and application continuity are essential requirements. The panel structure ensures reliable performance even in environments exposed to high thermal and environmental stress.

Main applications

- fire-rated partitions and wall linings

- non-combustible furniture

- public areas and cabins, both standard and luxury

- extremely humid environments such as galleys, bathrooms, swimming pools, and wellness areas

Fire-resistant sandwich panels: technical performance and application advantages

Fire-resistant panels must guarantee reliability not only in emergencies, but throughout the entire lifecycle of the vessel.

Certified fire resistance. Calcium silicate-based solutions with HPL facing can achieve classes up to B-30 on partitions up to 3 meters high, in compliance with marine standards. This ensures structural integrity and safety for the required time in the event of fire.

Performance in humid environments. Water absorption below 5% allows the panel to maintain dimensional stability and mechanical performance over time, even in environments subject to steam and condensation.

On-site workability. The ability to bond HPL laminates using standard adhesives and to machine the panel with common tools simplifies installation, reducing time, dust, and noise on site.

When to choose fire-resistant sandwich panels in marine applications

Fire-resistant sandwich panels are recommended for projects with fire-rated requirements, in public areas and shared spaces, in high-humidity environments, and in all contexts where safety, durability, and design must be combined.

Filippi 1971 develops technical panels for the marine industry with an industrial approach focused on safety and regulatory compliance. Solutions such as SEAWHITE HP meet these needs by integrating certified performance, reliability, and application quality.

FAQ – Fire-resistant sandwich panels

1. Are all sandwich panels fire-resistant?

No. It depends on the core, the facings, and the panel certifications.

2. What is the difference between fire-resistant and non-combustible?

A fire-resistant material slows down flames; a non-combustible material does not fuel the fire.

3. Is calcium silicate suitable for humid environments?

Yes, it has low water absorption and high stability.

4. Can fire-resistant sandwich panels be faced with HPL?

Yes, if they are designed to ensure compatibility between core and facing, as in the case of SEAWHITE HP.