Laminated panels are far more than simple functional elements – they define the appearance of modern interiors, motorhomes and boats. As a company specialized in the production of innovative wood and composite materials, Filippi 1971 stands for quality, technology and Italian design. For over fifty years, the company has been developing customized solutions for interior design, yacht construction and recreational vehicles. Filippi 1971 combines craftsmanship with sustainable production and a wide range of materials.

Whether decorative wood panels, HPL composite panels or lightweight sandwich structures – Filippi 1971 laminated panels combine aesthetics, durability and functionality at the highest level.

How to Use Laminated Panels Correctly

Laminated Panels for Interior Design and Furniture

In modern interior design, laminated panels are indispensable. They enable creative design concepts with warm, natural surfaces while offering high resistance. Filippi 1971 offers decorative wood panels and HPL laminates suitable for wall coverings, furniture and ceilings. Thanks to precise machining and digital surface finishing, the panels can be customized to the millimeter for every project – whether in residential, office or contract environments. Alongside visual appeal, functionality is also essential: scratch-resistant, moisture-resistant and easy to clean.

Laminated Panels in Camper and Caravan Construction

In caravan construction, weight and robustness play a central role. Filippi 1971 has established itself as a reference partner for leading motorhome manufacturers. The ultralight sandwich panels offer high stability with minimal weight and are available in numerous decors. I

nnovative bonding systems and moisture-resistant surfaces make them perfect for compact spaces subject to heavy use. Decorative wood panels also create a homely atmosphere – a crucial factor for comfort and design in mobile living.

Laminated Panels in Nautical Applications

In yacht and shipbuilding, laminated panels are exposed to extreme conditions: humidity, temperature fluctuations and vibrations. Filippi 1971 develops specially treated panels with high dimensional stability and rigid structure. The combination of marine sandwich panels and high-quality veneer surfaces enables luxurious interior fittings that are both functional and aesthetically refined.

Thanks to state-of-the-art digital printing technology, customized surface patterns can be created – from elegant teak to modern design textures.

Filippi 1971 Solutions for Laminated Panels

Thanks to decades of experience, Filippi 1971 combines craftsmanship, technological progress and Italian design to create durable, aesthetic and functional materials. The product range extends from lightweight sandwich structures to highly resistant HPL and compact laminate panels that excel in numerous applications.

Sandwich Panels with Digital Printing and Surface Options

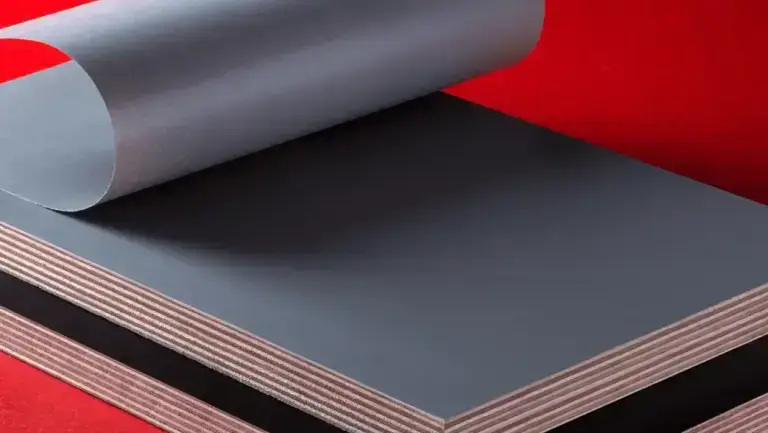

The sandwich panels developed by Filippi 1971 are the result of decades of research and experience. They consist of a lightweight core material combined with decorative and resistant surface layers.

Thanks to innovative digital printing technologies, almost unlimited design options can be achieved – wood effects, metal textures or customized graphics. These panels are frequently used in campers, boats and high-end interiors where low weight and refined design are equally important.

HPL and Compact Laminate Surfaces

For applications with high levels of stress, Filippi 1971 offers HPL and compact laminate laminated panels. These panels feature exceptional scratch resistance, chemical resistance and easy cleaning. They are ideal for public areas, sanitary facilities and technical applications.

Combined with precise edge finishing and a wide range of decors, they provide a durable and modern solution for demanding projects.

Technical and Regulatory Requirements for Laminated Panels

When selecting laminated panels, several technical and regulatory aspects must be considered.

- Fire resistance: depending on the application, panels must comply with current EU standards (e.g. EN 13501). Filippi 1971 offers materials with certified fire performance.

- Moisture resistance: especially in wet areas, campers and yachts, water-repellent structures are essential

- Surface quality: HPL and lacquer coatings protect against scratches and UV radiation.

Filippi 1971 advises its customers individually to identify the most suitable material for every application – from decorative wood panels to technical laminates.

Filippi 1971 – Company Profile and Core Competences

Filippi 1971 was founded in the province of Bergamo and has evolved from a small craft business into an international technology leader. The company combines traditional woodworking with state-of-the-art manufacturing technology.

Continuous research has led to innovative materials such as VittEr®, a sustainable, homogeneous material with high resistance and design freedom.

Today, Filippi 1971 covers various segments – from the production of wood and veneer panels to composite and sandwich systems and fully assembled components for recreational vehicles and boats.

The company’s core competence lies in combining aesthetics, lightness and environmental responsibility. Sustainability is a central principle: FSC® and PEFC™ certified wood species, energy-efficient processes and recycling solutions are firmly embedded in the company philosophy.

Contact Us for Further Information

Laminated panels are an essential element in modern design and construction concepts. They combine aesthetics, functionality and sustainability and offer countless design possibilities. With its experience and innovative strength, Filippi 1971 demonstrates that high-quality surfaces and technical precision can go hand in hand.

By combining traditional materials with high-tech solutions, the company creates products that meet the highest standards in architecture, mobility and design – durable, beautiful and future-oriented.