Okumé sandwich panels have become a preferred choice in the marine, construction, and outdoor furniture sectors due to their unique combination of lightness, strength, and versatility. Okumé plywood is particularly suitable for structures that require robust yet lightweight materials, making it ideal for boat applications. In this article, we will explore what Okumé plywood is, its main characteristics, practical applications, and how the solutions offered by Filippi 1971 meet the specific needs of the market.

What is Okumé Plywood and its main characteristics

Okumé wood is a highly versatile and durable material, particularly valued in the nautical sector for its lightness and strength. Derived from the Okumé tree, which grows mainly in Africa, this type of plywood is used to produce high-quality multilayer panels and sandwich panels. Its fine and uniform structure gives Okumé sandwich panels great strength without compromising weight, a key aspect for nautical applications.

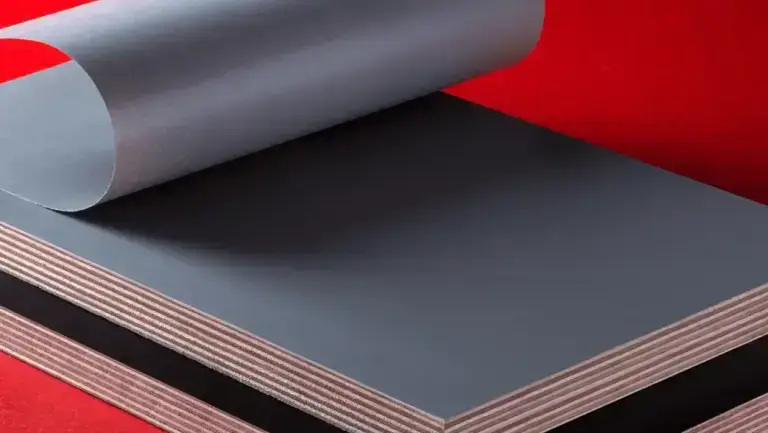

In Okumé plywood, sheets of wood are stacked and cross-glued to create an extremely strong and stable material. This production technique, combined with the excellent natural qualities of the wood, makes Okumé plywood ideal for structures that must withstand mechanical and environmental stresses.

Okumé Sandwich Panels: Structure, Composition, and Advantages

Okumé sandwich panels consist of layers of Okumé bonded to insulating materials, creating a structure that provides strength, thermal insulation, and acoustic insulation. The principle behind sandwich panels is simple: two layers of rigid material (in this case, Okumé) enclose a central material, usually an insulator, which can be PET, PVC, or other high-performance insulating materials. This construction ensures that the panel is lightweight, yet very strong and capable of withstanding mechanical stresses.

Compared to other construction materials such as birch or poplar plywood, Okumé stands out for its unique combination of lightness and strength. This makes it particularly useful in applications that require weight reduction without sacrificing mechanical resistance. Furthermore, its natural properties make it less susceptible to the corrosive effects of moisture and salt, an important advantage in the nautical sector.

Filippi 1971 sandwich panels can also be made with different combinations of materials. For example:

- SEACORE: Okumé and high-density rubber

- SEASAND HP: HPL (high-pressure laminate) and FIPRO® (a non-combustible fire protection board), providing superior mechanical resistance, ideal for extreme working environments.

FIPRO® is a construction panel made of expanded vermiculite, a natural mineral that, after heat treatment, becomes lightweight, non-combustible, and has excellent insulating properties. It is mainly used in the naval industry and in civil and industrial construction for wall construction, as a support element, and for thermal insulation and passive fire protection.

Each combination is designed to optimize performance in specific applications, such as maritime environments, where resistance to corrosion and weathering is essential.

Technical Characteristics of Marine Okumé Plywood

Marine Okumé plywood has superior properties compared to traditional plywood, making it particularly suitable for marine environments and applications requiring prolonged resistance to moisture and salt. Its main technical characteristics include:

- Warp resistance: its cross-laminated structure prevents deformation even under high humidity conditions.

- Mechanical strength: the combination of multiple layers gives the plywood remarkable robustness, making it ideal for applications such as boat construction.

- Thermal and acoustic insulation: Okumé sandwich panels can be equipped with insulating materials such as XPS, EPS, natural cork, or rubber, improving energy efficiency and acoustic comfort.

In Filippi 1971 solutions, panels such as SEACORK and SEALEAF STRONG are designed to maximize these features, meeting the specific requirements of the nautical and maritime sectors.

Okumé Texture and Finishes

Okumé plywood offers a natural aesthetic, with a fine and uniform texture that makes the wood suitable for high-quality finishes. Depending on the application, Okumé can be coated with protective materials to enhance durability and visual appearance. Filippi 1971 also offers various finishes, including PVC, veneers, HPL, VittEr®, etc.

Practical Applications: Where Okumé Sandwich Panels Are Used

Okumé sandwich panels are used across a wide range of sectors due to their strength, lightness, and insulating capacity. Main applications include:

- Marine and nautical sector: Okumé panels are ideal for the construction of boats and yachts, where lightness and resistance to salt and moisture are critical. Solutions such as SEAPET, SEACORE, and SEALEAF STRONG offer high performance even in extreme marine environments. Okumé panels are used for furniture, structural parts, flooring, bulkheads and partitions, removable floors, and hulls.

- Furniture and design: Okumé’s aesthetic qualities make it suitable for furniture applications requiring panels that are both strong and lightweight.

Where to Buy Okumé Panels: Filippi 1971 Offer

Okumé plywood panels are available from various specialized suppliers, including Filippi 1971, which offers a wide range of sandwich panels designed for specific applications in the nautical and furniture sectors.

Filippi 1971 uses Okumé in combination with innovative materials such as PET, PVC, and cork to meet specific needs. For example, SEAPET combines Okumé with PET, while the SEACORK system combines Okumé and cork, providing perfect solutions for insulation and durability in marine environments. Additionally, Filippi 1971 offers other solutions, such as SEALEAF STRONG, a combination of Okumé and PVC, providing superior performance in demanding applications like maritime use.

Conclusions

Okumé plywood is a versatile and high-performance material, applicable in numerous sectors such as nautical and naval construction—for structural components—and furniture—thanks to its unmatched resistance to moisture even in the harshest conditions. Its lightness, strength, and insulating capacity make it an ideal choice for those seeking innovative and durable solutions.

The advanced solutions offered by Filippi 1971, such as Okumé sandwich panels combined with PET, PVC, and cork, meet the demands of an increasingly challenging market, providing excellent performance in any environment.

Contact us for specific requirements, custom orders, or the creation of new personalized materials!

FAQ

- What are Okumé sandwich panels?

Okumé sandwich panels consist of layers of Okumé plywood bonded to insulating materials, creating a lightweight, strong structure suitable mainly for marine applications.

- What is the difference between Okumé plywood and marine plywood?

Okumé plywood is a specific type of marine plywood, known for its lightness, moisture resistance, and ease of work, particularly suitable for marine applications.

- What is the difference between Okumé plywood and marine plywood?

- Is Okumé wood suitable for humid environments?

Yes, Okumé plywood is particularly resistant to moisture and salt, making it ideal for marine and humid environments.

- Where are Okumé sandwich panels used?

They are primarily used in the nautical sector, in applications that require lightness, strength, and thermal and acoustic insulation.

- Why is Okumé plywood ideal for the nautical industry?

Due to its resistance to salt, moisture, and its lightness, Okumé plywood is perfect for the construction of boats and yachts.

- How to recognize a good marine plywood panel?

A good panel must have strong mechanical resistance, be made of quality materials (such as Okumé), and have a cross-laminated structure that ensures stability. - What finishes are available for Okumé?

Finishes include a wide range of customizable coatings: PVC, veneers, HPL, VittEr®, etc.