The recreational vehicle sector continues to grow across Europe, with the German market being one of the most demanding in terms of quality, lightness, durability, and compliance with technical standards. In this context, multilayer panels for motorhomes, specifically developed for caravans and RVs, are among the most commonly used materials for interior fittings and the construction of technical components.

Manufacturers of caravans and motorhomes have very specific requirements: low weight, long-term stability, precise workability, and low emissions. To meet these requirements, multilayer panels are today the most powerful solution, especially compared to lightweight panels for motorhomes or more cost-effective materials often used in DIY projects.

What characterizes a multilayer panel for motorhomes?

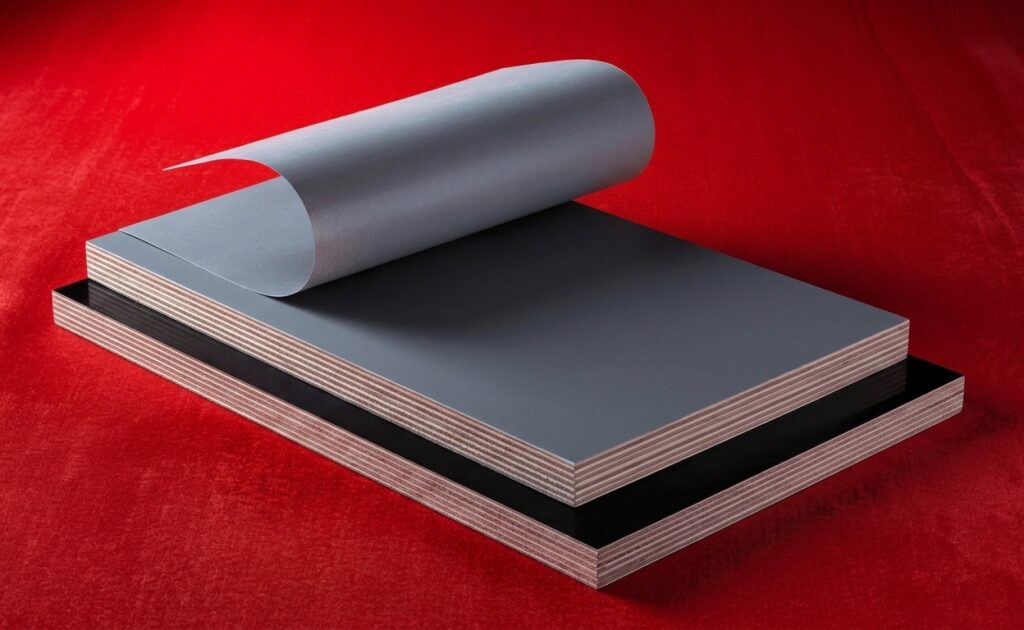

Multilayer panels for motorhomes are distinguished by their cross-layered structure, which ensures stability, mechanical strength, and precision in CNC machining. Compared to wooden panels for motorhome interiors, multilayer panels guarantee higher quality, particularly for industrial production.

Multilayer panels and motorhome interiors

More technically sophisticated multilayer panels, also known as multiplex panels, are used for motorhome interiors, where lightness and aesthetic finish must go hand in hand.

Multilayer panels and structural components

For bases, boxes, and modules requiring higher strength, multilayer panels are preferred over other panels due to their controlled rigidity.

Multilayer panels and lightweight walls

For surfaces that need to be lighter, sandwich panels for motorhomes are often considered in combination with traditional multilayer panels.

The most commonly used multilayer panels in the caravan and motorhome sector

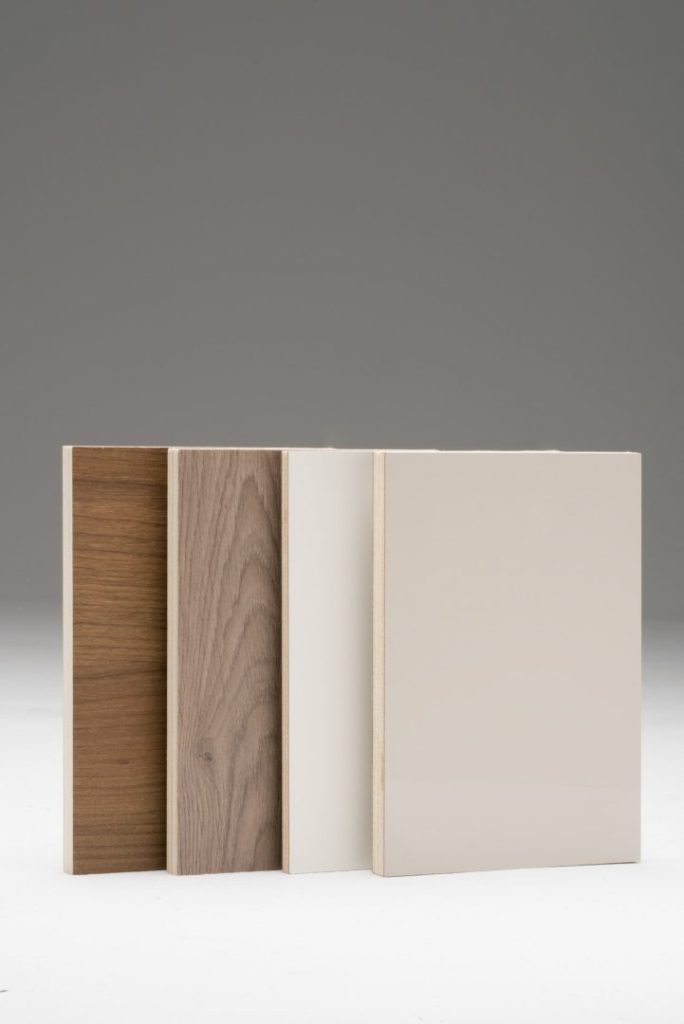

The choice of material affects the vehicle’s quality, durability, and overall weight. Here are the materials most frequently used in this sector.

Poplar plywood: lightness for motorhome interiors

Poplar plywood is one of the most popular furniture panels for motorhomes. It combines an optimal balance of weight and strength, precise workability, and compatibility with coatings and finishes.

Okumé multilayer panels: stability in humid areas of motorhomes

This material is ideal when moisture and condensation are critical factors: bathroom modules, kitchen bases, areas with a high risk of temperature fluctuations.

Birch plywood: mechanical strength for heavily loaded components

It is suitable for interior constructions subjected to stress, such as guides, bed frames, and areas exposed to long-term loads.

Falcata and Meranti: weight reduction

Falcata drastically reduces weight in lightweight constructions for motorhome interiors, while Meranti is used for aesthetic or technical applications with specific requirements.

Why multilayer panels are popular in the caravan and motorhome sector

The characteristics of multilayer panels for motorhomes fully meet the technical requirements of German manufacturers. Here are the main advantages.

Reduced and optimized weight in motorhome interiors. Reducing vehicle weight is crucial for improving fuel efficiency, available payload, and handling of special equipment. Multilayer panels, particularly poplar plywood, are the most efficient choice.

Stability and precision in processing. The cross-oriented fiber structure ensures stability even under continuous vibrations, typical of recreational vehicles.

Durability under varying conditions. The multilayer material retains its properties even with sudden changes in temperature and humidity.

Compatibility with technical coatings. The homogeneous surface material facilitates the application of HPL laminates and coated panels in motorhomes, often used to create harmonious and durable interiors.

Filippi 1971 solutions for caravans and motorhomes

Filippi 1971 offers specialized materials for the production of caravans and motorhomes, meeting the requirements of the German market and ensuring continuous supply even for large production volumes.

100% Italian poplar plywood. A lightweight, stable, and environmentally friendly material. Ideal for interior fittings, doors, wall cabinets, and technical components.

Coated particle boards. Filippi 1971 coated particle boards enable the creation of coordinated, uniform surfaces suitable for recreational vehicle interiors. Their aesthetics, durability, and color consistency are guaranteed.

Sandwich panels for motorhomes with XPS or PET core. The sandwich structure drastically reduces the weight of lightweight walls, ceilings, and interior panels. The XPS or PET cores provide stability and insulation.

HPL laminates and technical surfaces. HPL laminates and surfaces are ideal for kitchen counters, tables, and worktops in motorhomes, requiring scratch resistance and easy cleaning.

Choosing the right panel for each part of the motorhome

The right material combination makes the difference in the final quality of the vehicle.

- Interior fittings: poplar plywood, optionally veneered for a uniform appearance.

- Bathrooms and humid areas: okumé multilayer panels, designed for stability in high-humidity spaces.

- Light interior walls and ceilings: sandwich panels with a lightweight core (XPS/PET) to reduce structural weight.

- Kitchen counters and functional surfaces: HPL laminates on multilayer panels for high wear resistance and easy cleaning.

- Structural elements: birch plywood for components subjected to stress and load.

Certifications and corporate compliance

Filippi 1971 operates under a certified system ensuring consistent standards and full compliance with European regulations.

Certified material quality

The multilayer materials used come from controlled supply chains and comply with relevant EN standards. Emissions are verified according to E1 standards and, if required, CARB specifications for international markets.

Document management and traceability

All materials can be supplied with technical documentation, test reports, and certificates, useful for industrial manufacturers. This facilitates compliance with internal testing and quality controls required by German producers.

Production processes in accordance with European standards

Filippi 1971 applies processes compliant with European regulations on material safety, sustainability, and handling of potentially emissive substances. Internal quality controls ensure product uniformity and delivery repeatability, which is particularly valued by OEMs in the caravan and motorhome sector.

Reliability for series production

Continuity of supply, material stability, and documented compliance make the company a reliable partner for manufacturers producing recreational vehicles for highly regulated markets such as Germany.

Conclusion

Multilayer panels for motorhomes are currently the most reliable solution for manufacturers of caravans and motorhomes for the German market. They enable light, durable, and resilient interiors, meeting the needs of companies that require high-performance, easily workable materials compliant with European emission regulations.

The combination of multilayer panels, sandwich panels, and technical surfaces allows every project to be optimized both technically and aesthetically, ensuring consistent quality of the recreational vehicle over time.

Do you want to find the most suitable panel combination for your motorhome project?

We are happy to assist you in selecting materials according to your technical, aesthetic, and production requirements.

Frequently Asked Questions

1.What distinguishes a multilayer panel for motorhomes from a normal wood panel?

A multilayer panel for motorhomes consists of several wood veneers glued with fibers oriented in alternating directions. This ensures higher dimensional stability, bending strength, and more precise workability compared to particleboard and OSB panels.

2.What is the best multilayer panel for caravans and motorhomes?

It depends on the application. Poplar plywood is ideal for interiors due to its low weight, okumé is perfect for humid areas, and birch is recommended for parts subjected to higher loads. For lighter walls and ceilings, sandwich panels with XPS or PET cores are the most efficient solution.

3.Do multilayer panels meet German emission standards?

Yes. High-quality multilayer panels for motorhome construction comply with E1 or CARB standards, as required by German manufacturers, ensuring low formaldehyde emissions and interior safety.

4.Can sandwich panels completely replace multilayer panels?

No. Sandwich panels are ideal for reducing the weight of walls and linings, but multilayer panels remain essential for load-bearing elements, interiors, kitchen surfaces, and components requiring higher mechanical stability.

5.How do you choose the ideal panel combination for a motorhome?

The choice depends on the function of the components. Typically, poplar plywood is used for furniture, okumé for bathrooms, sandwich panels for lightweight surfaces, and HPL for kitchen counters. All configurations can be adapted depending on the production project.